Free Phase Remediation Equipment

LNAPLs are hazardous organic liquids such as gasoline, benzene, xylene and other hydrocarbons that do not dissolve in water. Hydrocarbons are one of the most common contaminants that require remediation due to the widespread occurrence of spills and leaks as a result of human activity such as natural resource exploration and production of oil.

Passive, Pneumatic and Electric Remediation Equipment

LNAPLs are lighter than water and does not dissolve in water. Since LNAPL’s density is less than water, LNAPL that is accidentally spilled or leaked can filtrate the ground but remains as a free layer on top of the groundwater.

These contaminants are widely recognised for the serious risks they pose to human health as well as to the environment. Risks from LNAPLs include:

- Explosion as a result of an accumulation of vapours from LNAPL

- Vapour intrusion

- Groundwater extraction and use

- Discharge of contamination into surface waters such as creeks and rivers.

Any LNAPL spills and leaks should be investigated and reported immediately to the relevant EPA bodies. While LNAPL can’t be completely removed, it should however be remediated to levels where it is no longer spreading and there are no unacceptable risks to human health, the environment and the beneficial uses of the groundwater.

Air-Met’s range of free phase remediation equipment include:

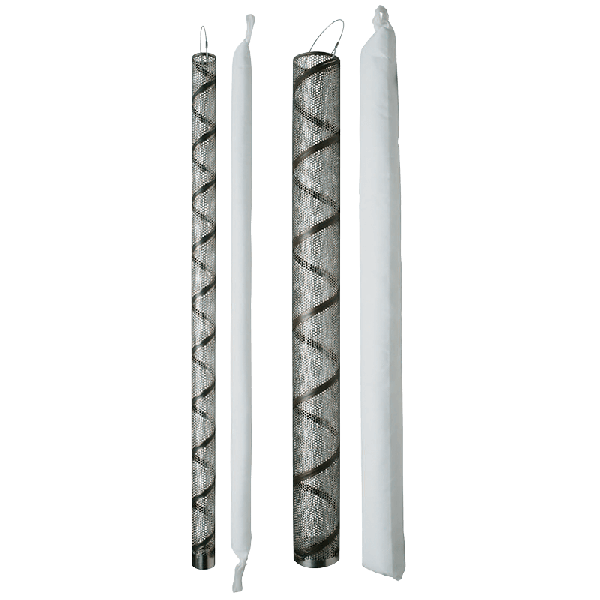

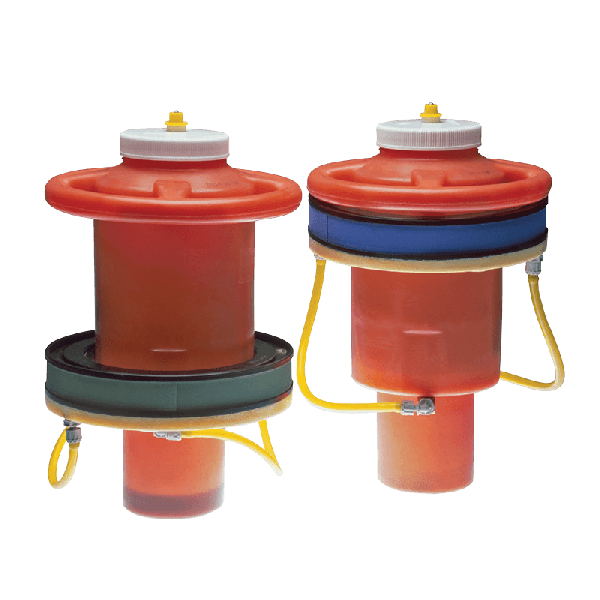

Passive Free Phase Remediation Equipment: Utilises floating intake filters that only allows free liquid phase products to enter or absorbent materials in cage bailers and no or very minimal water, passive skimming equipment accumulates product over time and do not pump the product to the surface, A low capital cost option that is ideal for skimming thin layers.

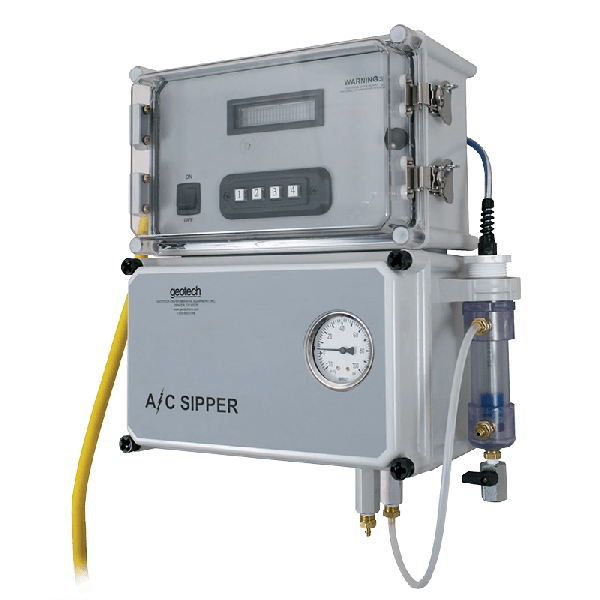

Pneumatic Free Phase Hydrocarbon Remediation Equipment: These active skimming systems utilise pneumatic pumps to separate floating free product to the surface and into recovery tanks. Ideal for lower product recharge rates.

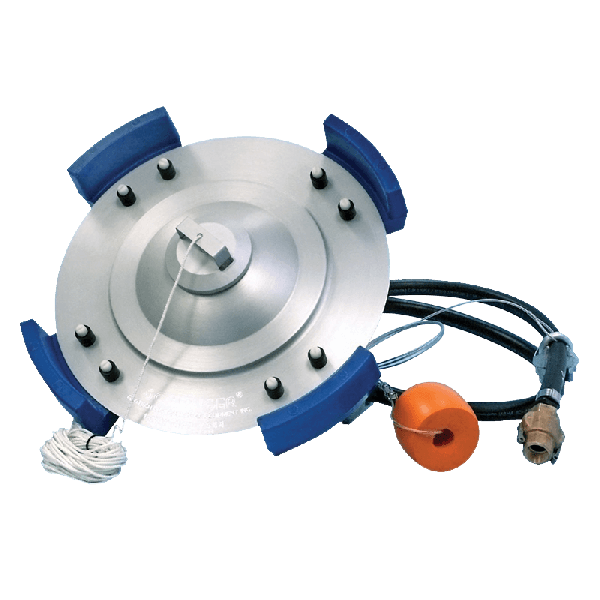

Electric Free Phase Hydrocarbon Remediation Equipment: Ideal for higher product recharge rates, active electric systems use electric pumps to automatically pump separated product to the surface and into recovery tanks. Electrical skimming systems use oleophilic/hydrophobic filters to separate the product with sensor probe systems to locate the hydrocarbon layer in the water therefore pumping only the product up to the surface.

For more information about Air-Met’s range of remediation equipment, contact your local Air-Met Scientific office today.