Instrument Management Systems And Docking Stations

Portable gas detectors are vital lifesaving safety devices that provide users with real-time gas concentration levels and alarm notifications which is why it is necessary to ensure that they are kept in optimal condition and function as intended. Instrument management systems and gas detector docking stations provide users with the ultimate flexibility in maintaining, calibrating, bump testing, and updating your gas monitor, along with the ability to store records for compliance purposes.

Commonly used in mining, smelting, construction, emergency services and other industries, instrument management systems and docking stations allow users to easily manage anything from a single gas detector to an entire fleet of gas detectors.

Air-Met Scientific supplies a range of Instrument Management Systems and Docking Stations available for sale and rental. Contact your local Air-Met Scientific to learn more.

Bump testing and calibrating gas detectors with docking stations

Bump tests and calibrations are both essential for the correct and accurate operation of a gas monitor. A bump test checks the ability of the instrument’s sensors to react to the target gases and verifies its ability to trigger an alarm. If the gas is detected and the alarm triggered, this means the device is safe to use as the instrument is functioning correctly and will alert workers should alarms exceed limit values. If the test fails, this indicates that the sensors will not react to the gas and trigger the alarm. As a result, the portable gas monitor should be sent in for repair or service. Air-Met Scientific recommends users conduct a bump test prior to using a gas detector to ensure that the sensors are functioning properly. A bump test does not however change the sensor memory.

In contrast, a calibration adjusts the monitor’s sensors to a known standard concentration of the target gas. Calibrating the sensors guard against wear and tear, sensor drift and gradual degradation over time whilst verifying the accuracy of the sensors. This ensures that the monitor is collecting and recording gas exposures accurately.

Docking stations such as the DSX Docking Station by Industrial Scientific provides users with the ability to easily manage and maintain their fleet of gas detectors. Docking stations allow users to conduct automated calibrations, bump tests as well as the ability to charge monitor batteries, perform record-keeping tasks, and perform gas monitor diagnostics, among others. This reduces the workload associated with managing a fleet of devices, whilst also reducing downtime.

Instrument Management Systems for Automated Gas Detection Fleet Management

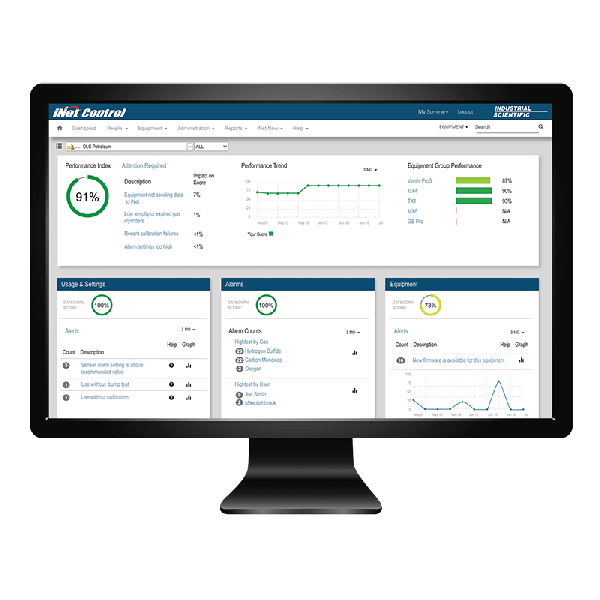

Instrument management systems, such as Industrial Scientific’s Indsci iNet, not only provide users with the ability to easily maintain gas detection equipment and manage compliance with automated calibrations, but can also perform bump tests, manage device warnings, firmware updates and provide reporting summaries for compliance. Additional features include providing unparalleled visibility into your gas detection program by allowing safety personnel to manage hazards, people, and equipment with one simple dashboard.

Contact your local Air-Met Scientific office now to discuss the best instrument management solution for your gas detection fleet.